Visual Boards for better productivity and efficiency

How will Visual Boards benefit my business?

Without Visual Boards, it’s much harder to see how efficiently your production line is operating. Any issues such as glitches or waste are not as easy to detect and are therefore more likely to continue and reduce profits. Investing in Visual Boards will mean a significant increase in manufacturing productivity, boosting profit margins and competitiveness. Digitalsoft’s extensive experience with large multi-national manufacturers and supply chain expertise enables the creation of innovative smart platforms to connect and empower businesses and their workforce by providing the right data to the right people at the right time.

The problems solved by Visual Boards

Until now, operators, supervisors and managers of the production line haven’t been able to be proactive because they haven’t had access to the critical data, features and solutions that Digitalsoft’s Visual Boards provide. This lack of visibility means problems can often go undetected and therefore inefficiency will result and dent profits.

How Visual Boards provide the solution

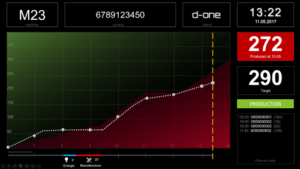

The real time data displayed on Visual Boards shows where inefficiencies lie and essentially predicts a problem worsens. Immediate access to this vital information aids the team in being able to address and resolve any issues before they spread and impact profit margins. Digitalsoft’s d-one visual management module is widget based, which allows users to design and configure their own bespoke KPI Dashboard to perfectly match their individual business’ needs. This is integrated with escalation management which sends e-mail and call alerts to rapidly communicate any issues to cross-functional teams for immediate action. This vital data can be displayed on any device such as tablets, smartphones or monitors on the shop floor.

Key features and benefits

Visual Boards improve manufacturing productivity by monitoring trends, observing and increasing efficiency and solving problems more quickly. This improved accountability leads to cost and waste reduction because Visual Boards illustrate:

- Real-time actual production vs target

- Real-time availability management for markets, channels & customers

- OEE, Performance & Cognitive Analytics with AI/ML

- Warehouse & Replenishment activities

- Metrics & Key Performance Indicators

- Manufacturing control and machine downtimes

Results

Operators, supervisors and managers have reported feeling empowered by Visual Boards to instill leaner, more focused and resilient working practices as a direct result of utilising the d-one factory visual management module.

Similar articles

How to get started

To find out more about d-one platform: