Driving Efficiency: Empowering Inventory Management with Technology

In the context of companies managing complex supply chains and processes, the term ‘balance’ serves as a concise descriptor for inventory management.

Indeed, as effective inventory management revolves around finding the perfect equilibrium between maintaining optimal stock levels and preventing overages or shortages, its primary goal is to guarantee the presence of the correct products and quantities at the appropriate locations when needed.

In 2023, manual inventory management is a thing of the past. Today, only technology provides the tools for truly efficient and real-time inventory management, regardless of the approach used (periodic, barcode, or RFID).

- This translates into:

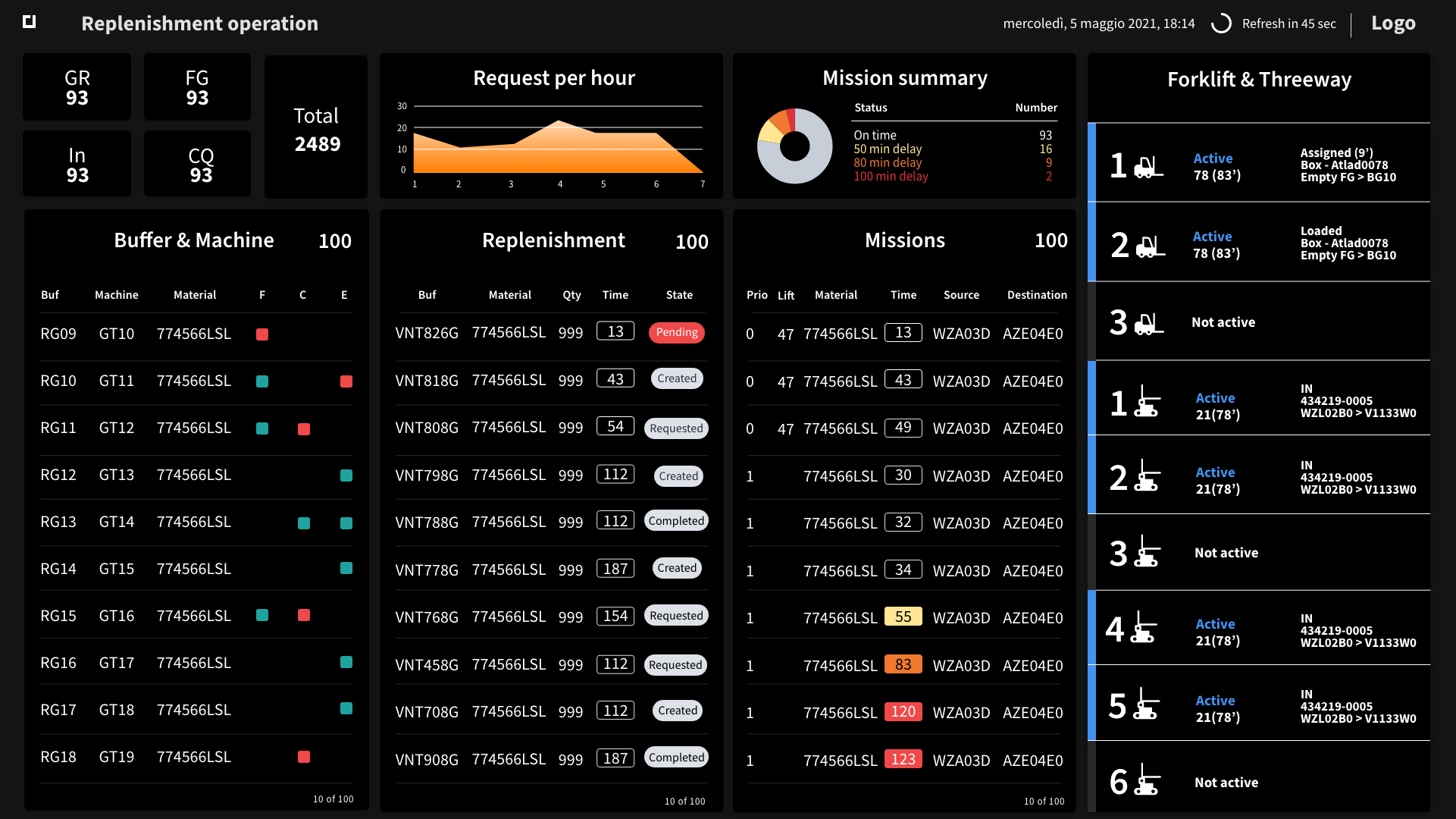

- Complete visibility across the entire operation

- Constant monitoring of inventory levels

- Data-driven forecasting and ordering processes

- Cost and cash flow optimization

In summary, inventory remains a crucial asset for any business. However, to remain competitive and outperform competitors, companies must embrace transformative technologies such as AI, ML, IoT, and more, to revolutionize their inventory management practices.

An efficient Inventory Management with d-one

D-ONE, our intelligent factory system, has been developed to address the problems of our customers and generate significant benefits that directly impact the performance of manufacturing plants.

Each module and functionality, built upon our extensive industrial production experience, strives to enhance efficiency and propel the transition towards the factory of the future. We are dedicated to addressing present challenges while concurrently prioritizing future evolution.

We recognized the significance of inventory management, often defined as one of a company’s most valuable assets. Our focused and deliberate efforts have led to the creation of a comprehensive solution designed to assist our customers in enhancing this aspect.

D-ONE offers a robust solution through its two modules, Planning and Warehouse, providing powerful tools for inventory planning, optimization, and management.

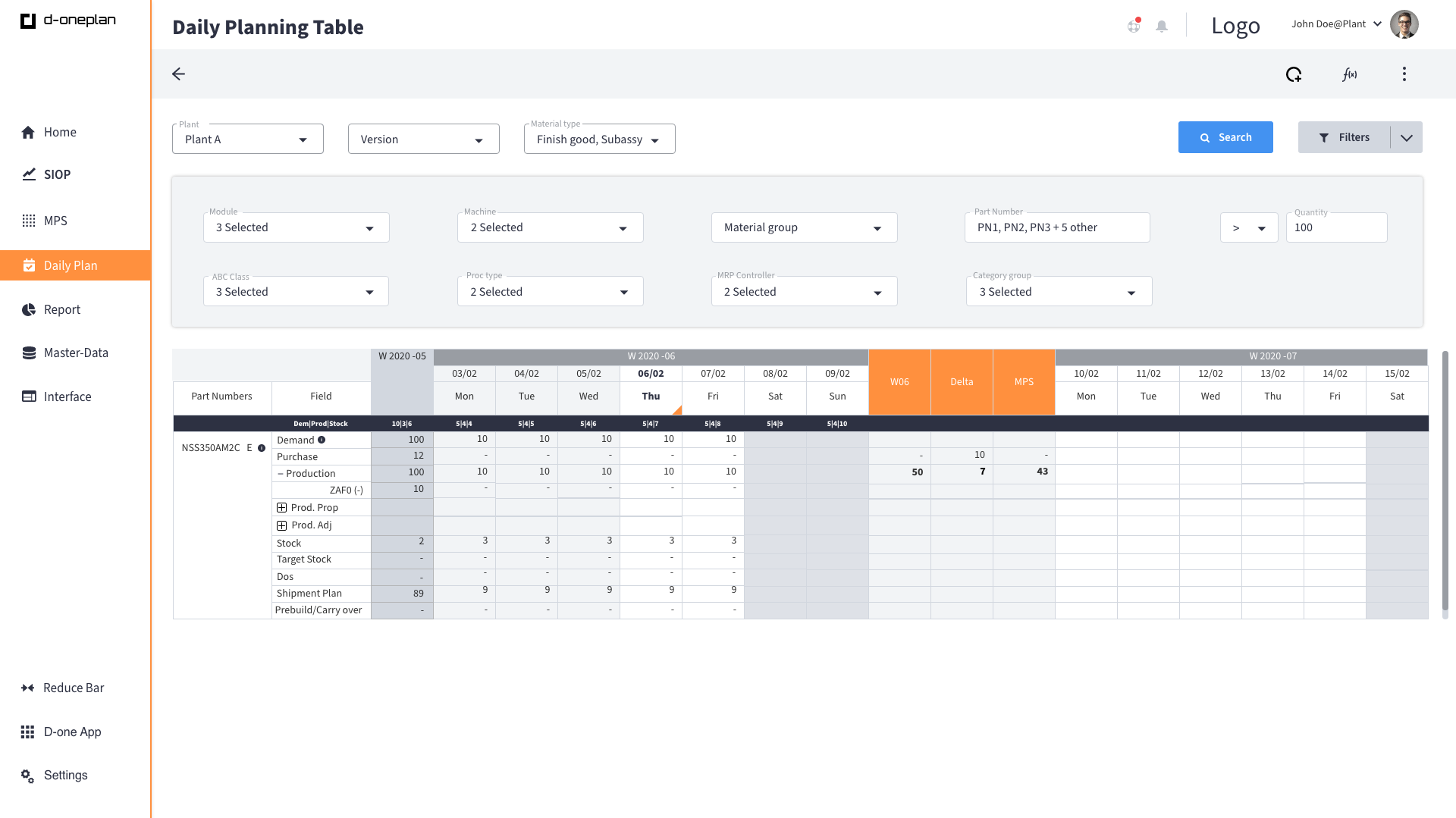

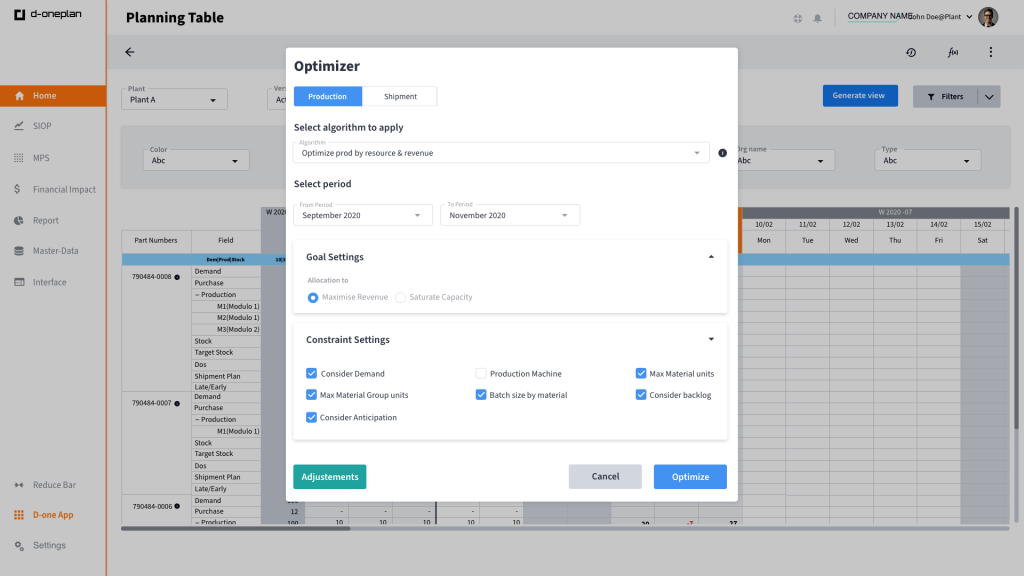

With the planning optimizer, you can effortlessly verify and simulate inventory projections, taking into account various levels and parameters, enabling:

- Inventory and shipment planning

- Optimization with multiple goals functions

- Fulfillment & OTC

- Stock projections based on purchased quantities, current stock levels, production and shipments.

- Target stock automatically optimized against demand forecast.

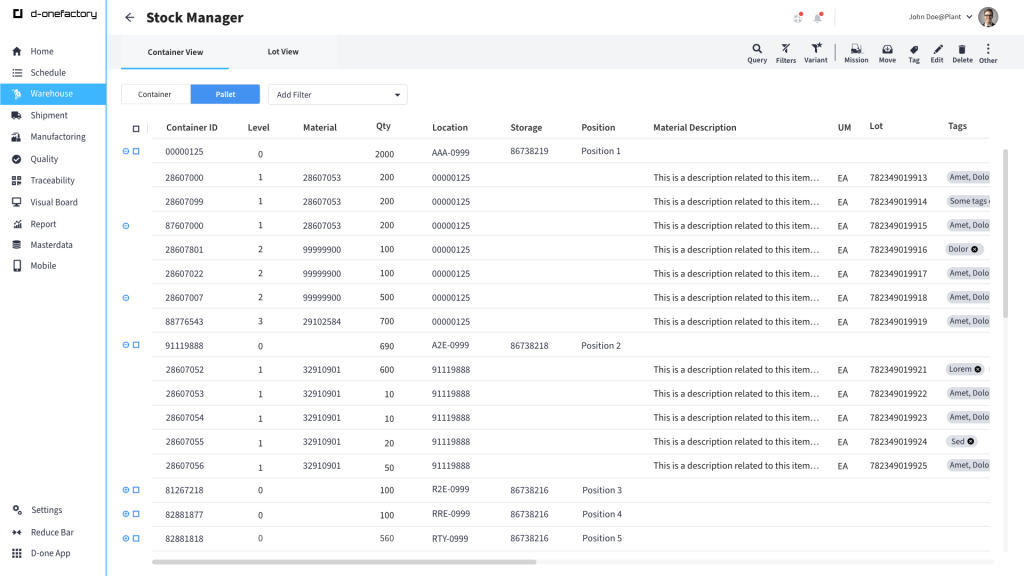

In the management side of goods, the integrated WMS provides you with the capability to:

- Inventory control. Physical vs Logical checks

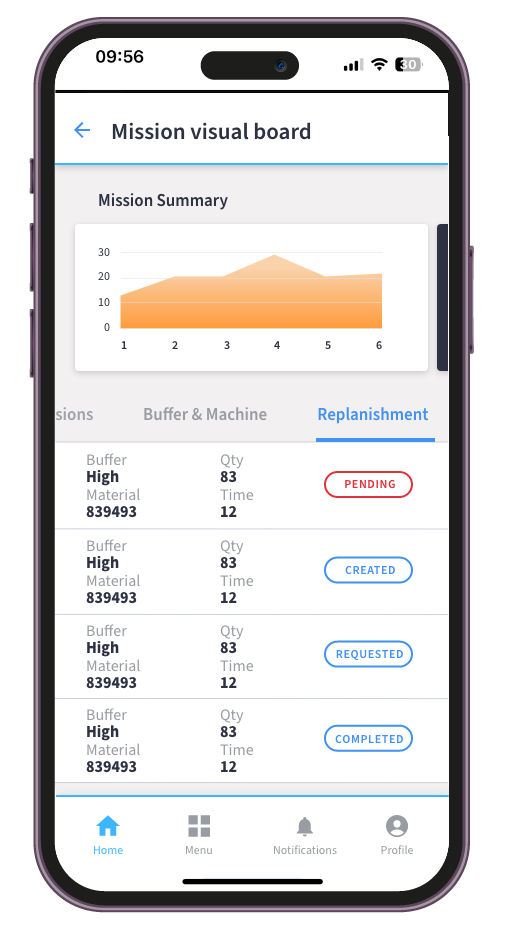

- Stock analysis & KPI for warehouse and shipment handling activities.

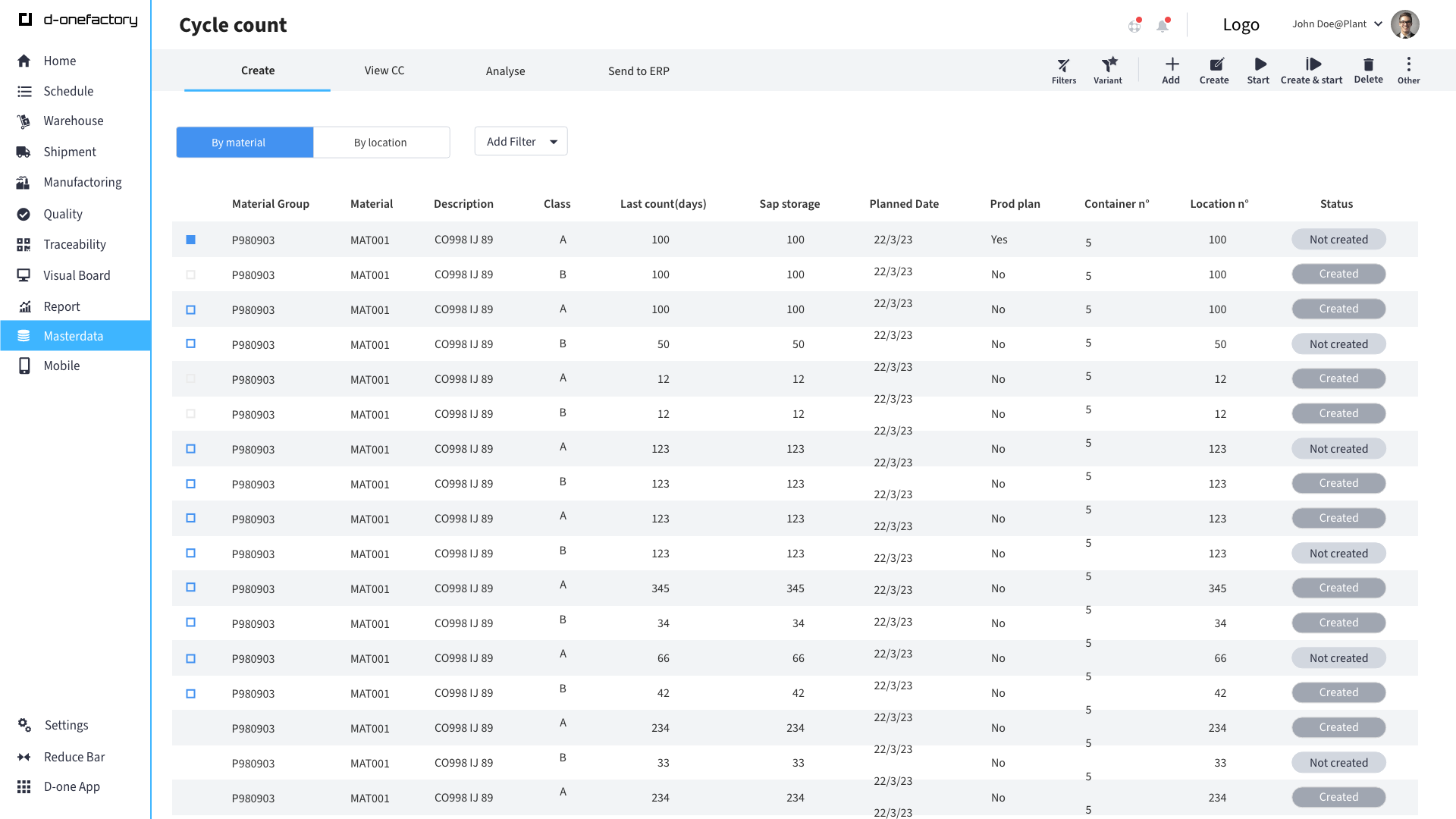

- Cycle counting with multiple strategies: ABC, value, specific material group, counter / re-counter / auditor.

- Annual physical stock count. Integration with ERP for annual financial adjustment.

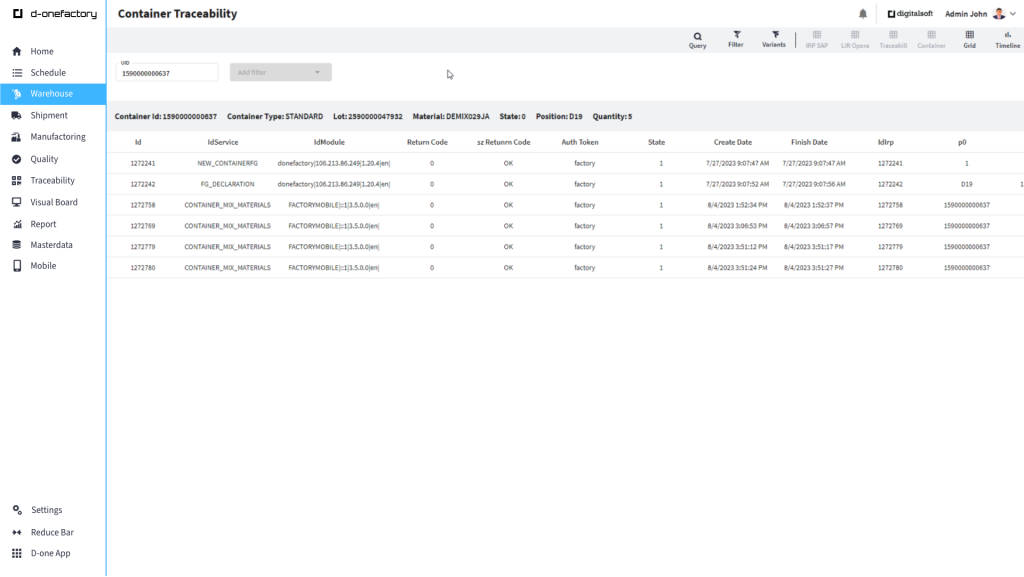

- Full track of the position and movements everywhere in the factory (traceability).

- Each movement is recorded with all relevant information log: users, datetime, source & destination.