Be Competitive:

the MES impact

The Manufacturing Execution System’s importance in today Global manufacturing scenario

In manufacturing companies, there is often a giant gap between ERP and production.

A Manufacturing Execution System with emerging technologies not only can fix the gap but can enable a greater level of operational efficiency and productivity.

A fully integrated and well-developed MES platform enables an essential alignment between information and physical flows. The first step to Industry 4.0 with countless benefits: better management of machines, people workload, and production volume generating a positive impact on the supply chain management as well as on customer satisfaction.

Manufacturing execution system impact

As underlined in the June 2022 Markets & Markets report: “The global manufacturing execution systems market size is expected to grow from USD 13.0 billion in 2022 to USD 20.0 billion by 2027, at a CAGR of 9.0%”.

The implementation of a manufacturing execution system (MES) today is crucial for manufacturing companies as it represents a key step towards their evolution to the so-called “Future Factory”.

MES is a driver for a connected factory. Efficient information flow across the factory is an important factor in enabling efficient production activities. Intelligent MES with integrated IIOT can be used for collecting machine data, tracking goods, real-time monitoring inventory, and reporting manufactured products passing through the supply chain process. Connected manufacturing solutions also help in the easy flow of information throughout the entire supply chain, which makes it easy for companies to respond to changing market conditions.

Real-time information helps manufacturers in being reactive and responsive, identifying risk issues, and achieving production according to customer needs. The increase in manufacturing activities globally for mass production, along with quality improvement, is driving the need for advanced tools and software systems. This need can be catered to with advanced production systems and methods offered by manufacturing execution systems.

Even if different in terms of functionalities and ease of use, MES software packages share a common key role: they manage, monitor and synchronize the entire production process, with the aim of increasing their efficiency. It enables production, equipment, human resource, materials, maintenance and quality management and supports managers to make real-time decisions and effectively balance production capacity to achieve production performance and goals. To work properly MES needs to integrate with other key systems, whether it’s hardware (machines, sensors, PLC), or business management software like ERP, IBP, etc.

D-ONE FACTORY (MES)

Digitalsoft d-oneFactory is an Intelligent MES aims to bring to life what we call ‘responsive manufacturing‘. Responsive manufacturing is:

- modern factory management with reliable real-time data, visual boards, predictive and actionable insight

- strong integration between shopfloor execution and planning. Modern Factory Management with an end-to-end view via mobile App and visual Boards

- data and analytics management to detect deviations in the manufacturing process at an early stage, providing alerts to responsible persons via a digital escalation process

- standardized manufacturing processes and systems, with integrated quality control and full product traceability

- effective and reactive service work (e.g., maintenance) using a single integrated tool, focusing on preventive maintenance, and providing value-added services

- full traceability with material, operation, and machine data. Meaningful, easy-to-use digital work instructions and quality checks.

- simplified IT landscape enabling top-notch processes and a high degree of automation

How can d-one Factory put in place all these improvements?

With its different functionalities, designed to enable intelligent management of manufacturing processes:

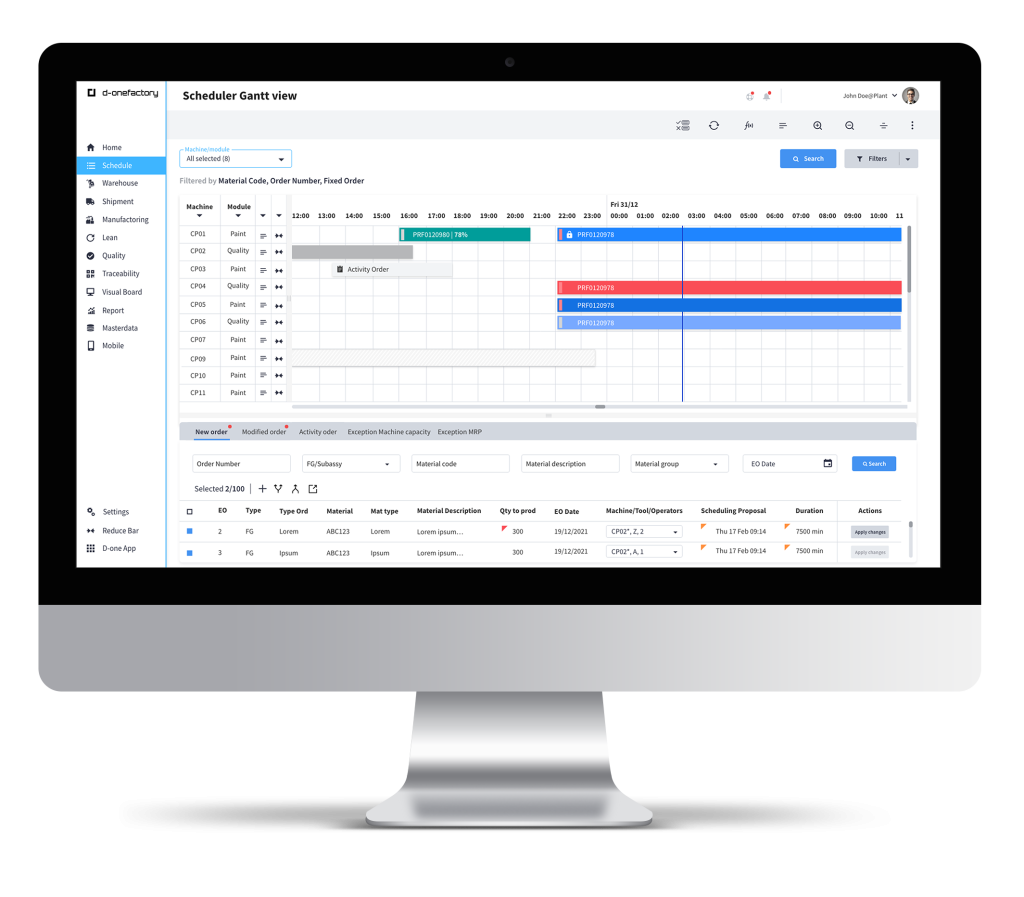

Detailed Scheduling

Supports AI/ML in creating the best-detailed production plan, driving optimized production sequences by machine with the best utilization of the factory capacity, while taking into account potential production constraints. Through the integrated Clear To Build feature the system will quickly show materials availability ensuring your production plans are feasible and leading to fewer production losses in execution.

Manufacturing management

Execution of production, displaying all information regarding current production order, real-time machine and process data (e.g.: temperature, pH, calibration, etc). Production order management, goods declaration, material consumption and replenishment with lean manufacturing techniques (PULL strategy, e-Kanban,..). Resource & Labor management. Easy direct access, thru the mobile app, to operating instructions, breakdown declaration and machine downtime.

Maintenance

Management of the maintenance process, from operators, call to restart of production. Enabling the Predictive maintenance with Machine learning algo. Collection and tracking of downtime information, automatic from the machine or manual from operators with related causes. Spare parts management. Option to record and recall the video of activities (knowledge base). Real-time downtime information enables to make immediate reactivity, increasing operation efficiency, while long-term data collection aids the detection and investigation of production process-related problems. Notification and proper escalation to cross-support functions involved, supervisors and managers.

Visual Management, Reports & Analytics

All organizational levels have their personalized view with relevant, real-time information on progress of activities in the factory and the end-to-end supply chain. OEE reports help find and solve production bottlenecks. Analyses and prioritization of the causes behind lost capacity.

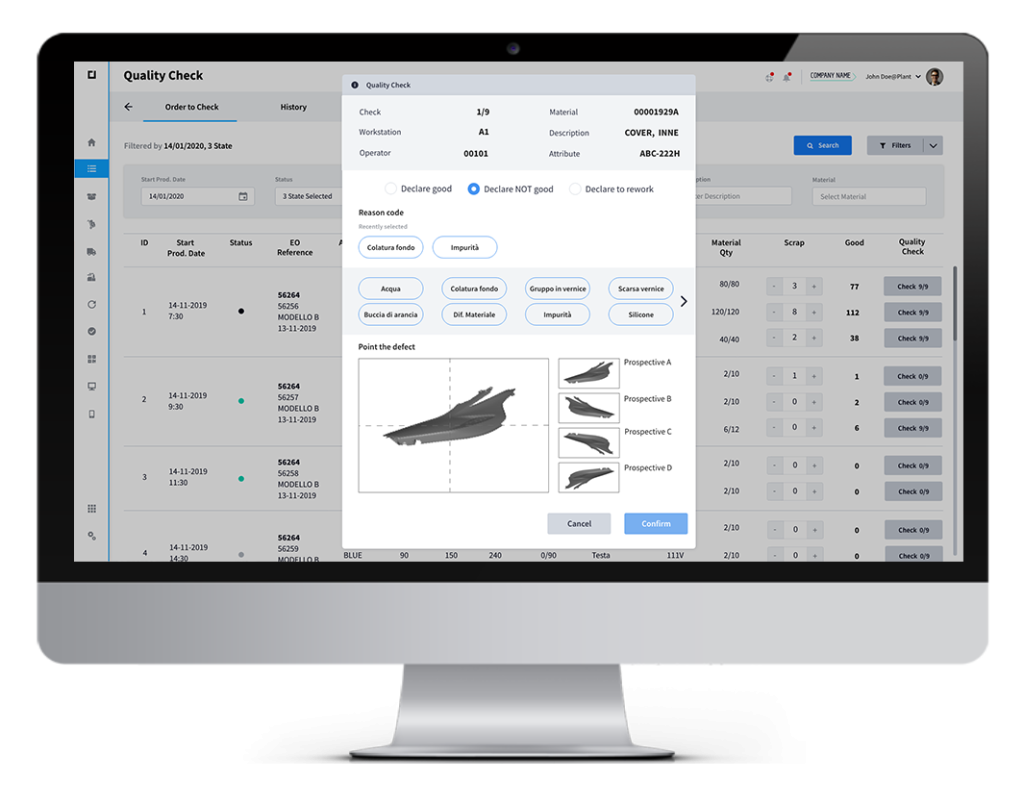

Quality

Closed-Loop Quality Management to improve the quality of products and processes. Work instruction for operators. Perform a checklist before the start of new production orders. Declaration of defects during the manufacturing process. Quality alert, parts inspection and scrap & rework, work instruction, process control & Poka-Yoke. Remote Quality Monitor: Monitor and predict the effect of deviating temperature, relative humidity (see IIOT) and process control with SPC.

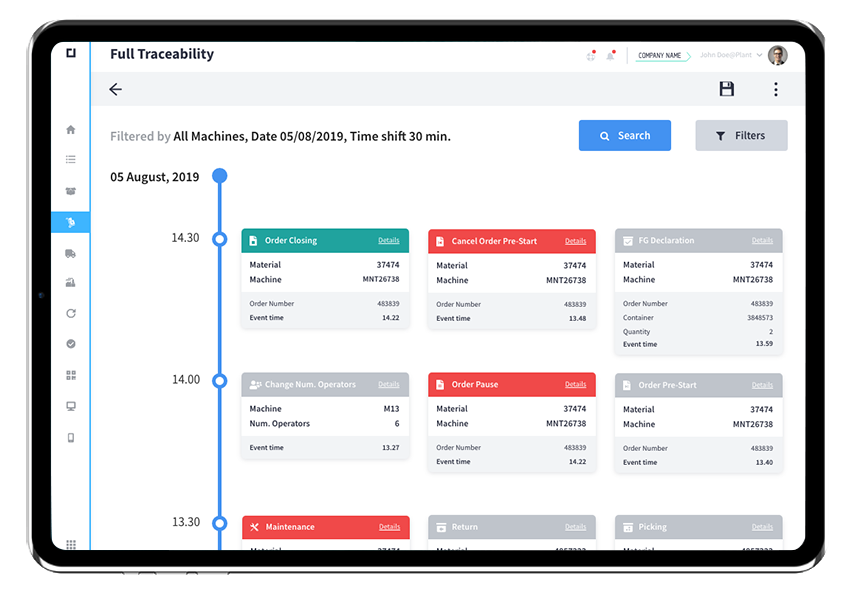

Traceability

End-to-end traceability with machine, order, materials and operations (e.g. start/stop, setup, maintenance, quality, safety, etc). Collect specific product process data from the machine (e.g.: temperature, calibration,…). Ability to collect and trace the information for batch and individual devices (by serial number).

IIOT and Machine Data collection

Smart integration with various type of Machines, Utilities, PLC and sensors to ensure collection of relevant data for optimized control. Connecting data and processes, IIOT with big data analytics will enable a more reliable monitoring across the actors involved in the operations to predict and detect problems and prevent outages early. Enable a real time factory environment for control, optimized and responsive operations while elimination of compartmentalized data.

The future of MES is simplicity and ease of use vs the legacy old style MES systems, historically not very user-friendly or at least inflexible.

The power of d-one MES module lies not only in the above features but also in how it is designed.

Based on modern technology (AI/ML, API, Cloud, etc) and on the most intuitive UX, the entire d-one platform is modular, and it easily integrates with the hardware and tools already in use. This enables our customers to solve their current Supply Chain challenges while planning their leap into the “Future Factory”. Indeed, by gradually adding its natively integrated modules, the platform can easily scale up to follow your business evolution without having to deal with multiple systems with complex and high-cost integrations. Furthermore, the Saas business model allows for quick ramp-up, experimentation, and tailored to each need.

The d-one Factory platform can solve challenges that traditional MES cannot, by rapidly connecting people, processes, machines, and systems in one or more production plants and creating a real and immediate advantage for the workforce.

Here we can list some benefits like:

- improving efficiencies

- reducing downtime

- increase customer service level

- enabling paperless and uninterrupted workflow, lower error rate

- reducing indirect cost and non-value added activity

- lower work-in-progress inventory

We partner with our customers to innovate together and to create solutions able to fit their expectations and requirements.